Video

Description

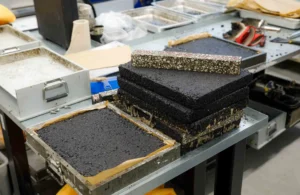

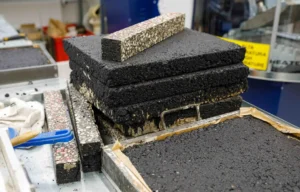

Recycling of end-of-life tyres remains a challenge: most are landfilled or incinerated, with CO₂ emissions, and the energy recovered is 6-7 times less than the energy used to produce the tyres. Traditionally, recycled rubber is used for elastomer additives or playgrounds, but it produces dangerous polycyclic aromatic hydrocarbons. The use of crumb rubber in asphalt concrete has not been widespread: the wet method is energy intensive and causes delamination, while the dry method only partially replaces fine aggregates. This project proposes a new approach, reactive extrusion technology, which could lead to a multifunctional and intelligent modifier. It is not only able to regenerate aged bitumen and improve self-healing properties, but also to promote the recycling of tyres and asphalt concrete, creating a sustainable and competitive solution.

Achievable results

This project proposes to develop a technology for the recycling of end-of-life tyre rubber using a reactive extrusion method to create not only an elastomer additive but also a multifunctional and intelligent modifier capable of regenerating aged bitumen, improving its self-healing properties and partially replacing it. Such an additive could contribute not only to the recycling of tyres but also to the recycling of asphalt concrete.

Benefit

Society as a whole is the users of public infrastructure, including citizens and businesses, who have a stake in improving the quality of roads and the environment. It is important to note that one of the expected results of this project is that road surfaces modified with RE-TECH-ROAD elastomer additives show better sound attenuation properties, which is a particularly suitable solution in urban environments. This is in line with EU climate objectives and will contribute to the circular economy by offering a sustainable and environmentally friendly alternative to current road construction materials. It is important to note that previous technologies using waste rubber in roads, playgrounds, etc. were not environmentally friendly as this rubber emitted volatile organic compounds (VOCs) which are harmful to the environment and humans. However, the technology developed in this study, where the rubber is devulcanised, significantly reduces VOC emissions to a significantly low, tolerable level that poses no risk to human health.