Description

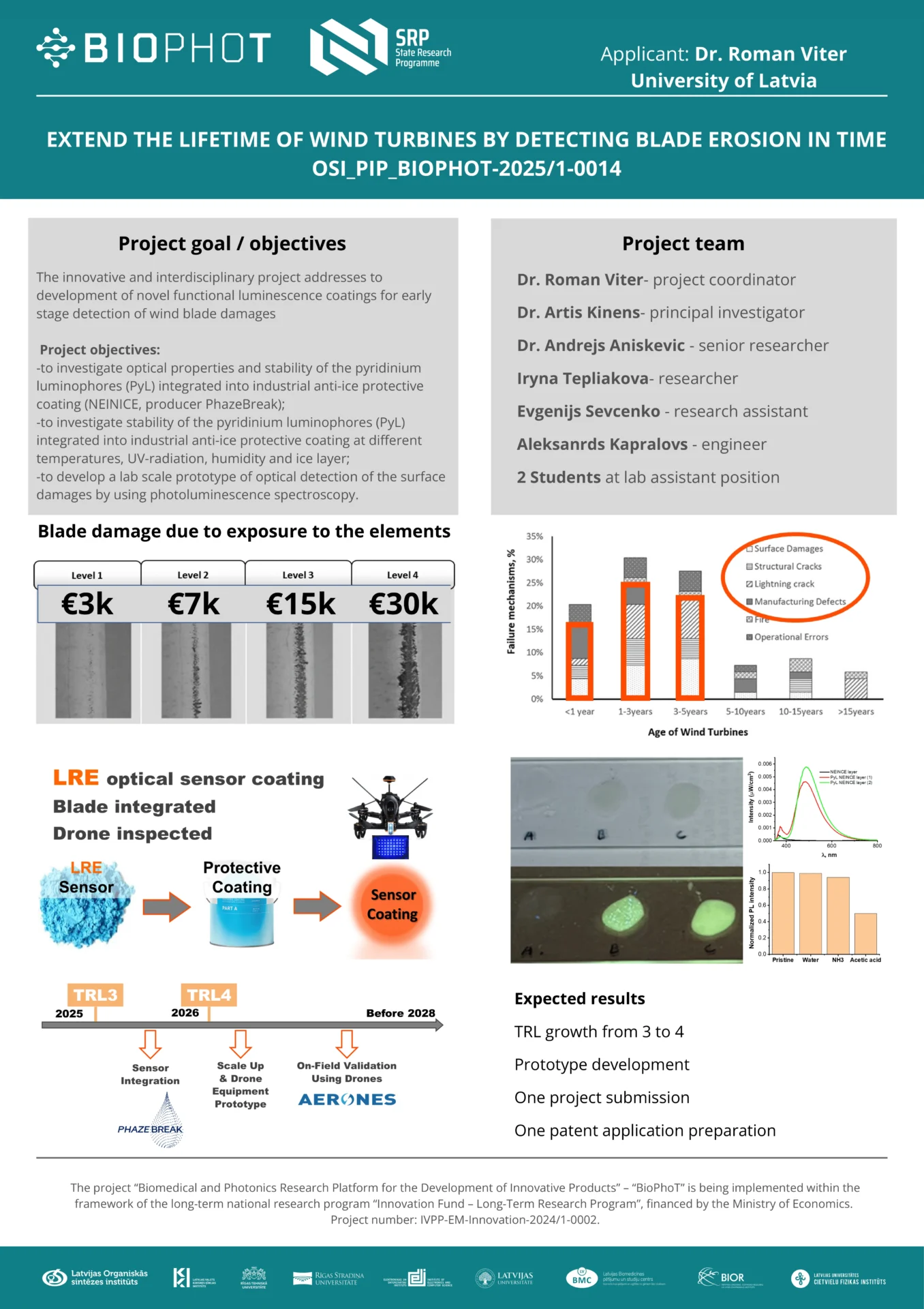

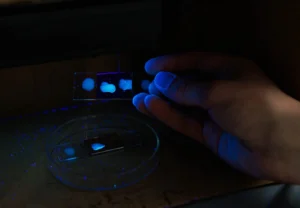

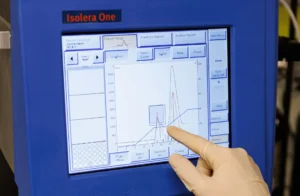

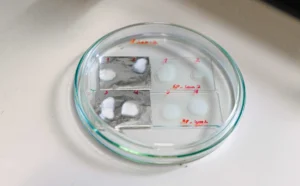

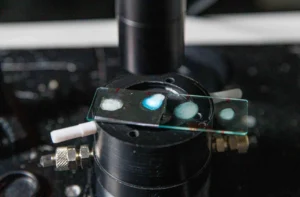

This innovative and interdisciplinary project aims to develop new functional fluorescent coatings for the early detection of wind blade damage. The main hypothesis of the project is that novel chemically stable pyridinium phosphors (PyL) integrated in the top protective coating allow the detection of mechanical cracks, delaminations and defects along the wind vane surface due to changes in luminescence intensity. The objectives of the project are focused on the integration of PyL with commercially available NEINICE epoxy resins, the study of optical properties and stability under realistic conditions (UV, temperature, humidity and ice layer). A laboratory scale prototype will be developed for surface testing and model surfaces with defects. A summary report of the tests will allow the optimisation of the PyL chemical structure and the alignment of PyL with w/w NEINICE. The project will increase the TRL from 3 to 4. One patent application, one M-Era-Net project and one publication will be submitted. Dissemination of results will be presented at 2 industrial exhibitions, 1 conference and 2 innovation events (presentations). The project has close collaboration with potential customers/end users PhazeBreak and Aerones. The intellectual property rights obtained in this project will be transferred to PhazeBreak and Aerones for further commercialisation in accordance with the internal rules of the University of Latvia.

Achievable results

BladeLife has set the following objectives:

- to investigate the optical properties and stability of pyridinium phosphors (PyL) integrated in an industrial anti-icing coating;

- to investigate the stability of pyridinium phosphors (PyL) integrated in an industrial anti-icing coating under different temperatures, UV, humidity and ice conditions;

- develop a laboratory-scale prototype for optical detection of surface damage using photoluminescence spectroscopy.

- increase TRL from 3 to 4-5 at the end of the project;

- file 1 national patent application.

Benefit

Environmental benefits: Effective decision-making on timely repair of wind blades will reduce significant damage to wind blades, recycling costs, air, land and water pollution from damaged wind blades.

Economic benefits: the technology will provide cost and time savings for wind blade maintenance and increase the efficiency of energy conversion.

Research benefits: New knowledge on the development and tailoring of new nanomaterials with improved properties and knowledge transfer for applications.

The socio-economic impact of the project depends on improving the quality of life of the Latvian population, creating new products and new jobs through the knowledge of new functional materials and the development of new diagnostic methods for wind blades.

Global impact: a new tool for the green transition.