Description

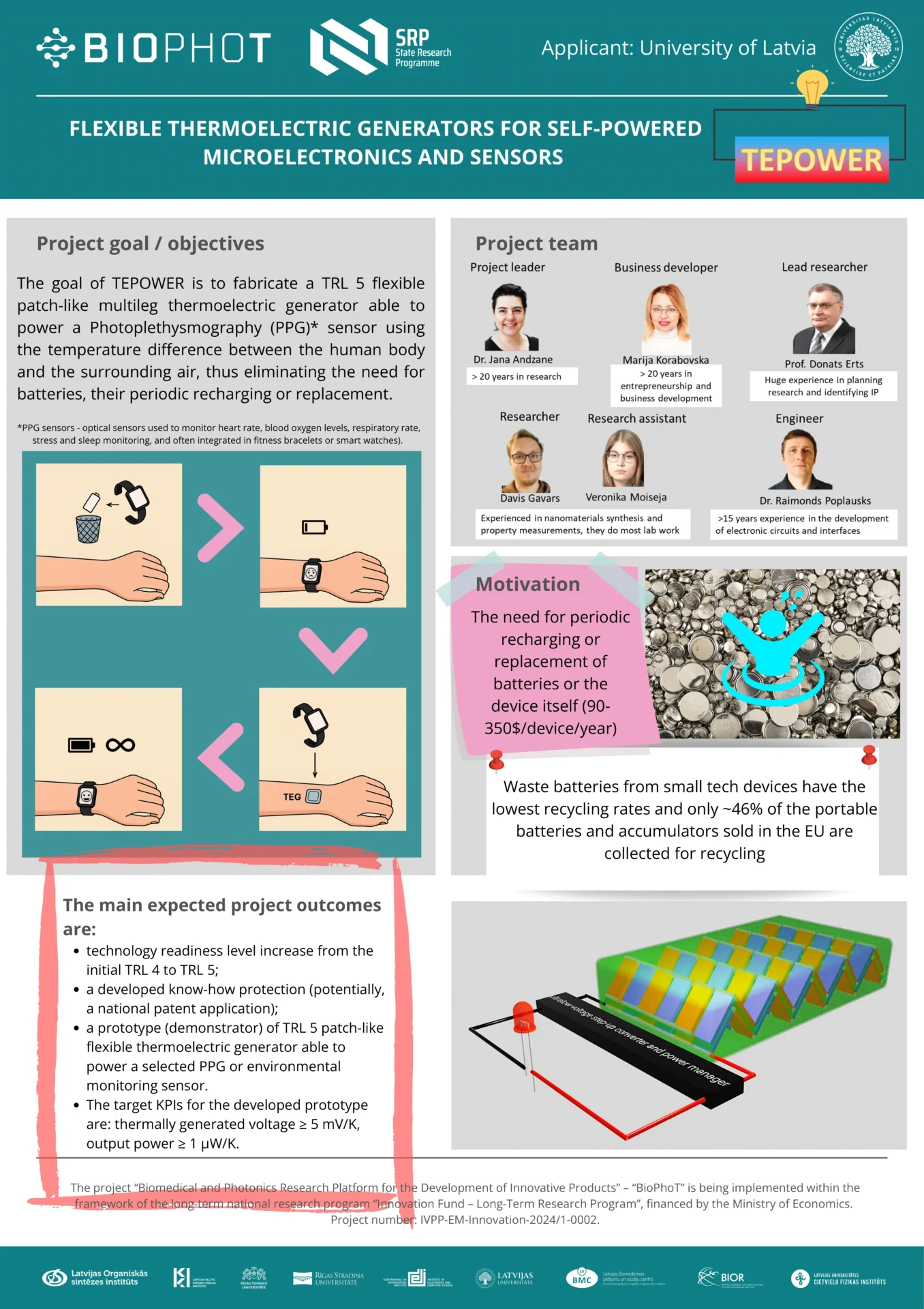

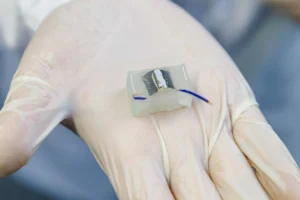

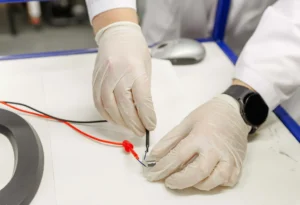

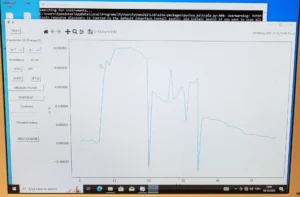

Personal wearable electronic devices such as photoplethysmography (PPG) sensors and environmental monitoring sensors are rapidly becoming part of our everyday lives. However, these sensors require an external power source to function properly and run on batteries, which limit their lifetime and require periodic recharging or replacement of the batteries or the device itself, as well as contributing to increasing battery waste. Powering these devices with thermoelectric generators, exploiting the temperature difference between the human body and the environment, can help overcome the limitations of battery use. The project aims to improve the applicant's previously developed technology for the fabrication of flexible heterostructure-based thermoelectric thin films from TRL 4 to TRL 5 by developing a flexible, patch-like, multi-leg thermoelectric generator (TEG) capable of powering a commercial PPG or environmental monitoring sensor using the temperature difference between the human body and the ambient air. This objective is to be achieved by: (1) an innovative deposition method that allows multiple p-n-leg pairs connected in series to be deposited in two synthesis sessions; (2) an improved, bend- and stretch-resistant, accordion-like arrangement of p-n-leg pairs in the TEG structure that does not require additional wiring and allows a large number of p-n-leg pairs to be efficiently arranged in a limited space.

Achievable results

The aim of the project is to improve the applicant's previously developed technology for the fabrication of flexible heterostructure-based thermoelectric thin films from TRL 4 to TRL 5 by developing a flexible, patch-like, multi-leg thermoelectric generator (TEG) capable of powering a commercial PPG or environmental monitoring sensor using the temperature difference between the human body and ambient air.