Description

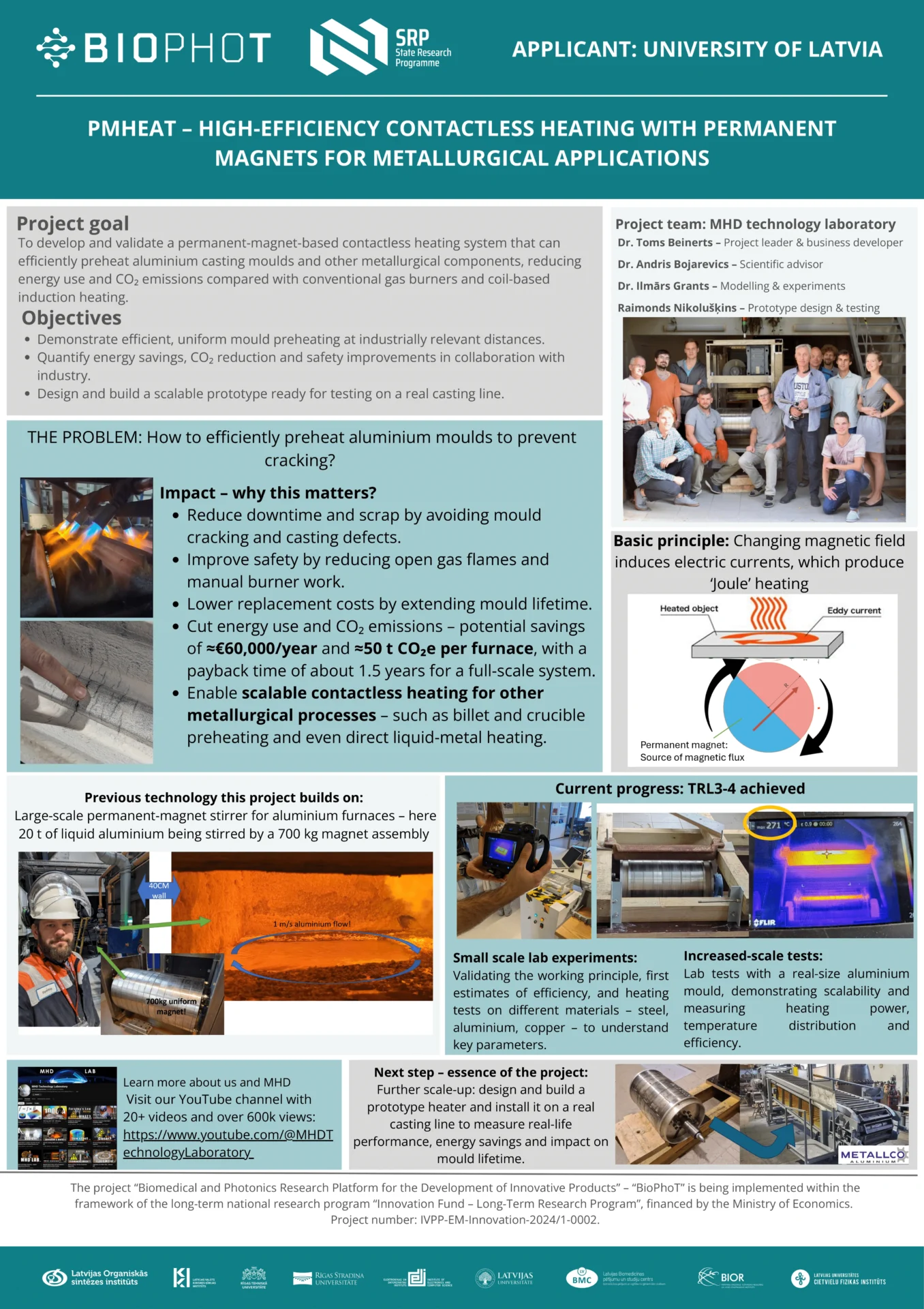

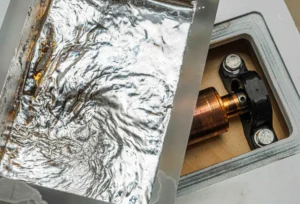

The aim of this project is to develop and validate a new, highly efficient non-contact heating technology based on rotating permanent magnets (PM) for metallurgical applications, in particular aluminium casting. Unlike traditional induction heaters, which suffer from high coil losses and limited heat transfer, our system is able to provide over 90% efficiency at distances of 5-50 cm by inducing eddy currents without direct electrical contact. As no high power converters and no cooling are required, the system is simple, scalable and maintenance friendly. Based on previous successful implementations in the PM mixer industry, the project involves heating steel moulds, replacing inefficient gas burners and achieving up to 60 t CO2 savings per year per line. The project will combine multi-physics modelling with experiments, optimising heating uniformity and reducing oxidation risks. The result will be validated prototypes, models and patentable solutions that will contribute to the electrification of metallurgical processes and meet the objectives of the European Green Deal.

Achievable results

Develop and validate a new generation of non-contact electromagnetic heating system based on rotating permanent magnets, achieving significant efficiency gains (>90%) compared to conventional methods.

Demonstrate the application of the technology in aluminium metallurgy, starting with the heating of moulds, and prepare it for further use in heating furnaces, ingots, billets and other metals.

Develop the prototype to TRL 3-4 and carry out industrial tests with potential users.

Ensure IP protection (patent application) and prepare a commercialisation roadmap (licensing or spin-out company).

Fostering interdisciplinary scientific collaboration in photonics, materials science and engineering, developing new competences for research and innovation.

Benefit

Environmental benefits: significant reduction of CO₂ emissions (~60 tonnes per year per installation) by replacing low-efficiency gas burners with green electric heating; direct alignment with the European Green Deal and the Sustainable Development Goals.

Economic benefits: cost savings for industry (~60,000 €/year per installation due to energy efficiency, long lifetime of the forms and reduction of CO₂ taxes), short payback time (1-2 years), which strengthens the competitiveness of companies.

Social benefits: increased occupational safety for users by reducing the risk of explosion during the mould heating process, as well as promoting a shift towards safer and more environmentally friendly production methods.

Scientific and innovation benefits: new scientific knowledge on the interactions between magnetic fields and metals, strengthening of interdisciplinary cooperation and involvement of young researchers in the creation of innovative technologies.

Wider societal benefits: reduced industrial carbon footprint contributing to climate targets while creating new high value-added jobs and an innovation ecosystem in Latvia and Europe.